Solutions for

Threaded Assembly

We specialize in world-class torque control and error-proofing products and offer a vast array of premium and value-engineered solutions for your assembly needs.

Our Solutions

Express

The ASG Express product line specializes in industrial, light and general assembly tools and accessories with a focus on threaded assembly tools and aids.

Shop Now

Precision Fastening

Premium threaded assembly solutions crafted for manufacturers demanding tight tolerances and superior error-proofing.

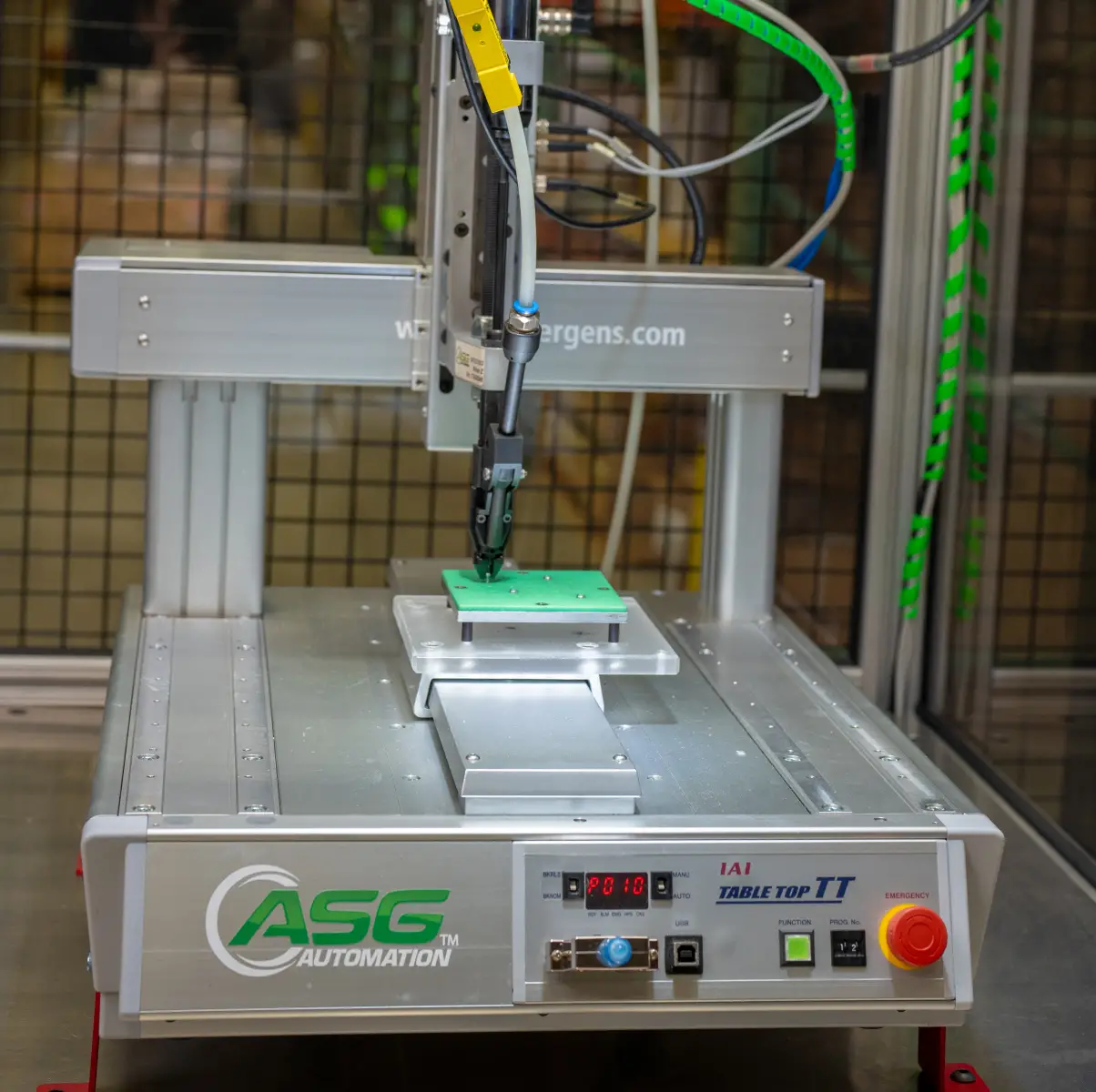

Automation

Custom-engineered solutions for assembly integration. The ASG Automation group tailors unique solutions to complex applications.

Shop Featured Products

HIOS HP-100 TORQUE TESTER

HIOS Torque Tester for applications between 1.0 and 10.0 N.m of torque. Verify the accuracy of screwdrivers and manual torque tools.

Shop Now

EZ-9000GR TAPE DISPENSER

Limited time offer: Receive a free roller and blade kit with the purchase of an EZ-9000GR tape dispenser. Offer ends June 28, 2024.